Who we are?

JST is a professional Wooden Products Manufacture in Chachoengsao, Thailand since 2000’y.

Our plant now measures 400,000 ft2 land with more than 120,000ft workshop.

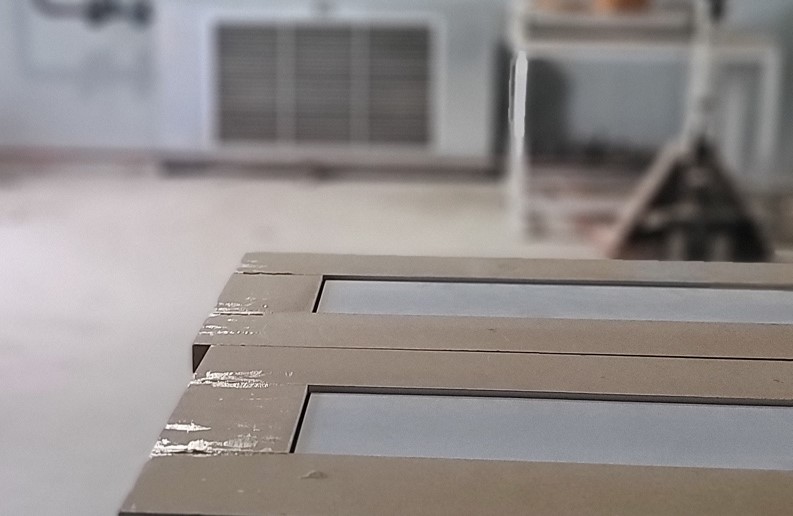

We have two Auto- production facilities with fully settled equipment.

We are making quality Frame and Frameless kitchen & bath cabinets under US industrial standards